Aluminum Alloy Radiator Guard - Precision Stamping for Custom Designs

Stamping and surface treatment for aluminum radiator guards in motorcycle use

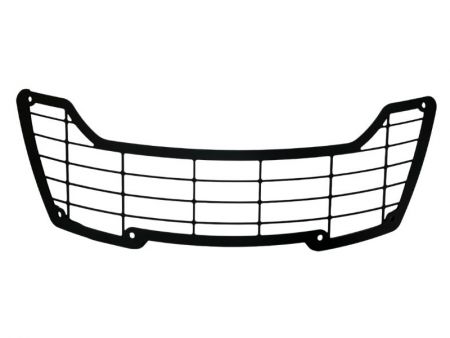

Shih Yeh's custom aluminum alloy radiator guard is meticulously crafted to ensure both protection and aesthetic appeal for motorcycle radiators, demonstrating our advanced metal stamping capabilities and expertise in bringing your complex design concepts to life with precision and durability.

Durable Materials and Multi-step Stamping Process

This radiator guard is made from high-quality aluminum alloy, providing excellent strength, corrosion resistance, and lightweight durability. The guard is formed from a 2mm thick aluminum plate through a multi-step stamping process, which shapes the material with precision and consistency. Each stage in the process ensures that the guard maintains its structural integrity while accommodating the intricate design, making it highly durable for long-term use in harsh conditions.

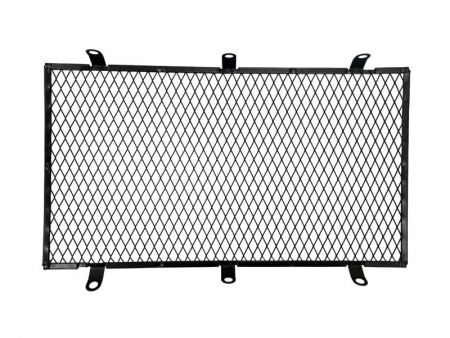

Intricate Hexagonal Mesh Design

The guard features a hexagonal perforated pattern, which improves airflow and offers maximum protection. The stamping process creates approximately 800 hexagonal holes within a 230mm x 230mm area. This complex pattern, with 1.3mm narrow edges between perforations, presents a significant challenge during production, especially in 2mm thick aluminum plate. Our specialized punching die and multi-step stamping process ensure consistent hole shapes and precision, maintaining the integrity of the pattern throughout the manufacturing process.

Accurate Fit and Custom Surface Finishes

To guarantee a precise fit, we control deformation at every stage of stamping, ensuring that the guard aligns perfectly when attached to the radiator and integrates seamlessly with mating parts. For surface treatment, we offer a range of finishes specifically suited for aluminum parts, including anodizing to enhance corrosion resistance and durability. Additionally, we can do sandblasting to create a matte texture on the surface, improving the aesthetic appeal while preparing the material for further treatment. These finish options ensure the radiator guard meets both functional and visual requirements, in line with customer specifications.

By partnering with us, clients gain access to a wealth of metal stamping expertise, advanced production solutions, and customized production tailored to their unique design requirements. Our focus is on delivering precision parts that meet both technical needs and visual appeal, making us a trusted partner in the motorcycle manufacturing industries.

- Related Products

Custom Aluminum Mudguard for Motorcycles - Advanced Stamping and Anodized Finish

This motorcycle mudguard is made from durable aluminum alloy, designed for both strength and precision....

DetailsFine-Blanked Aluminum Motorcycle Luggage Rack – Chamfered & Anodized Finish

Shih Yeh's motorcycle luggage rack is expertly crafted from premium 4mm-thick aluminum alloy,...

DetailsPrecision Stamped Metal Covers, Shields, and Guards for Motorcycles

Shih Yeh has extensive experience manufacturing a wide range of complex metal covers, shields,...

Details

Aluminum Alloy Radiator Guard - Precision Stamping for Custom Designs | Tooling & Metal Fabrication for OEMs – On-Time, On-Spec | Shih Yeh Taiwan

Precision-focused metal manufacturing company offering CNC machining and tooling solutions for custom needs.

Shih Yeh Ind. Co., Ltd. delivers Aluminum Alloy Radiator Guard - Precision Stamping for Custom Designs services backed by decades of expertise. Our ISO 9001-certified facility ensures top-tier quality from tooling development to finished parts. We’re trusted by international brands for our efficient workflows, tight tolerances, and consistent results. Whether for automotive components, medical tubes, or motorcycle fittings, we craft custom solutions that exceed expectations.

Shih Yeh Ind. Co., Ltd. is a leading Stamping, Machining, Welding, Surface Treatment, Polishing manufacturer and exporter from Taiwan, serving the Precision metal parts manufacturing industry industry since 1990. With over 25 years of expertise in precision manufacturing, Shih Yeh delivers high-quality, custom-engineered solutions tailored to global client needs.