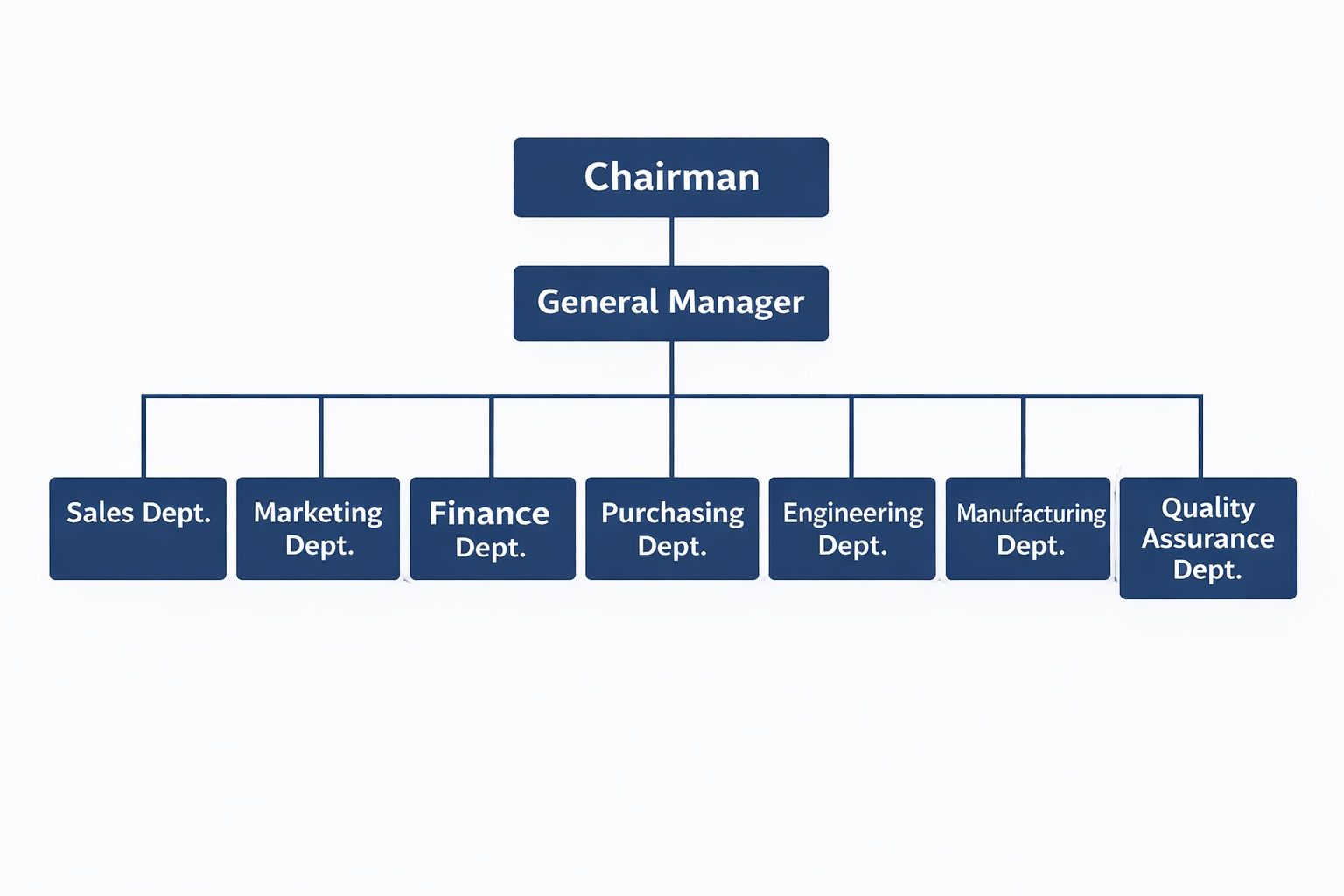

Organization Structure

Professional Team: Process-Driven Expertise for Custom Metal Manufacturing

Shih Yeh has extensive experience in custom metal stamping and precision metal manufacturing, serving a wide range of industries including motorcycles, medical devices, industrial equipment, and semiconductors. With a process-driven organizational structure, we integrate demand evaluation, tooling and process development, mass production manufacturing, and quality control into a complete manufacturing system. This approach enables customers to transform design drawings into metal parts and assemblies that are stable, repeatable, and ready for long-term mass production, making Shih Yeh a reliable manufacturing partner.

Sales Department|The Starting Point for Manufacturing Solutions

The Sales Department is the first step for customers entering custom metal stamping and mass production manufacturing. The team focuses on aligning product requirements with manufacturing conditions by evaluating design drawings, application needs, process feasibility, material selection, tooling direction, and production volume requirements. By introducing manufacturing-oriented thinking at the early development stage, the Sales Department helps reduce downstream process risks and improves project feasibility, ensuring metal components transition smoothly into mass production.

Engineering Department|Core Expertise in Tooling Development and Stamping Processes

The Engineering Department focuses on metal stamping tooling development and forming process design, with capabilities covering progressive dies, single-stage dies, and multi-process integrated stamping solutions. These capabilities support complex structures and diverse industry applications. From tooling structure planning and die fabrication to trial runs and process refinement, the engineering team establishes repeatable and mass-production-ready processes, ensuring consistent forming quality and dimensional stability during high-volume production.

Manufacturing Department|Execution Strength in Metal Stamping and Mass Production

The Manufacturing Department is the core of Shih Yeh’s mass production capability, responsible for executing metal stamping, machining, welding assembly, and surface finishing processes. Supported by extensive shop-floor experience and standardized process management, the manufacturing team reliably advances projects from pilot production to high-volume manufacturing while meeting design specifications and delivery requirements. Continuous optimization of production lines and process efficiency enables stable, large-scale supply of metal parts.

Quality Department|Process-Based Quality Control for Stable Production

The Quality Department implements a process-based quality control system covering incoming inspection, in-process inspection, final inspection, and mass production quality tracking. Through measurement equipment, dedicated inspection fixtures, and standardized inspection procedures, the quality team maintains real-time control of process conditions. This ensures metal stamped and formed components meet customer specifications and industry standards in dimensions, appearance, and functionality, supporting long-term production stability.