Welding

Precision Welding Capabilities for Metal Fabrication

At Shih Yeh, we go beyond metal stamping to provide value-added services such as welding, offering a complete solution for our clients' metal component needs. By integrating welding into our production process, we streamline manufacturing and enhance the functionality and durability of custom metal parts.

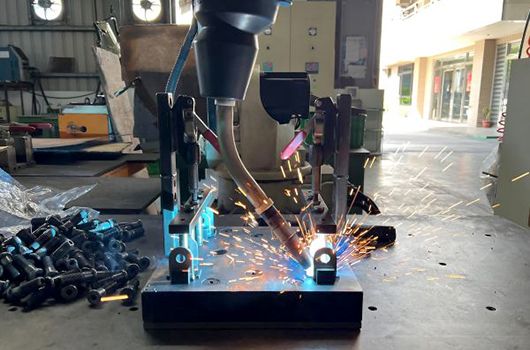

Advanced robotic and manual welding options

Shih Yeh's welding capabilities include cutting-edge robotic welding systems and precise manual welding techniques. Robotic welding offers consistent quality, high-speed production, and precise repeatability, making it ideal for large-scale projects with stringent requirements. For more intricate or specialized tasks, our skilled technicians utilize manual welding methods, allowing us to adapt to various project needs and deliver tailored solutions.

Expertise in MIG and TIG Welding Techniques

Shih Yeh's in-house team is highly experienced in Metal Inert Gas (MIG) and Tungsten Inert Gas (TIG) welding processes. MIG welding is suitable for high-speed and robust connections, and its faster production rate makes it a more cost-effective option. Meanwhile, TIG welding ensures precision and clean finishes for intricate components. This dual expertise enables us to handle a wide range of materials and part geometries, ensuring optimal results for every project.

By combining advanced technology with craftsmanship, Shih Yeh delivers high-quality welding solutions that meet and exceed client expectations. Whether it's robotic efficiency or the adaptability of manual welding, we ensure your custom metal components are built to last.

- Related Products

Steel Motorcycle Headlight Bezel with Spot-Welded Brackets and Chrome Finish

This motorcycle headlight bezel is crafted from high-quality steel using advanced manufacturing techniques. The bezel is formed through drawing and undergoes...

DetailsPrecision Metal Fabrication and CNC Machining Drop Link for Motorcycles

This high-performance drop link for motorcycles combines precision fabrication with strict quality control to ensure superior durability and structural...

DetailsSteel Hook Assembly for Winch - Precision Stamped and Welded

This steel hook assembly for the power tools is composed of a bar and stamped components. The 10mm diameter bar, approximately 500mm in length, undergoes...

Details