Metal Stamping

Metal Stamping Services for Diverse Applications

Metal stamping is a high-efficiency manufacturing process that uses a press and die to transform flat metal sheets into desired shapes. Recognized for its ability to produce complex parts with consistent precision, cost-effectiveness, and scalability, it is an essential solution across industries. With over 30 years of expertise, Shih Yeh excels in precise dimension control, meeting stringent tolerance requirements to ensure customer satisfaction.

Stamping Capabilities

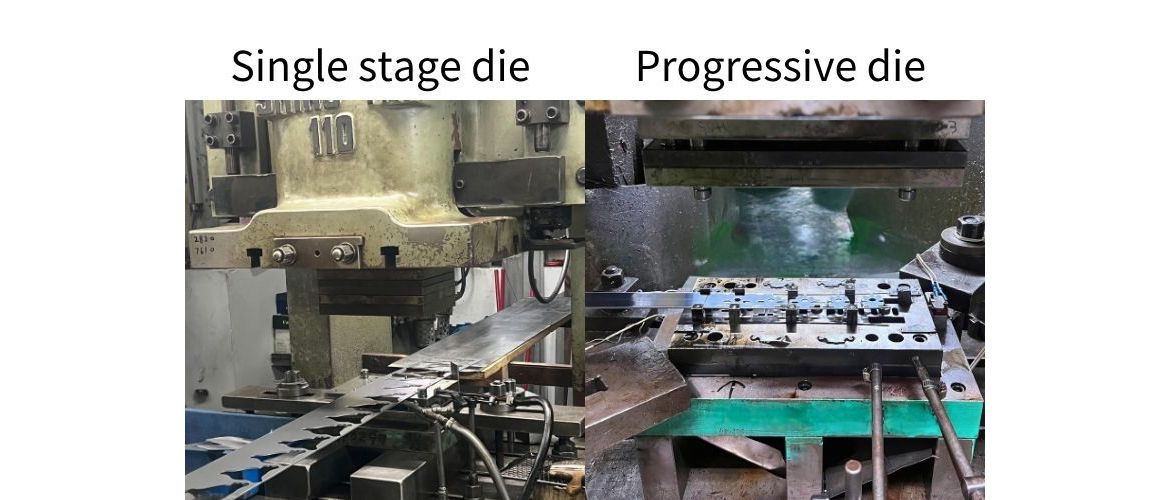

Shih Yeh's stamping processes include both single-stage stamping and progressive stamping, offering the flexibility to meet a wide range of production needs. Single-stage stamping is ideal for producing larger components in smaller quantities, while progressive stamping ensures high-speed production of small, intricate parts.

Advanced Equipment

Equipped with stamping machines ranging from 3 to 250 tons, Shih Yeh can handle projects of varying sizes and complexities. From finely detailed electronic components to medium and large stamping parts for automotive, motorcycle, and machinery, our versatile equipment ensures consistent quality and reliability.

Material Expertise

Shih Yeh works with a variety of materials, including steel, stainless steel, aluminum alloy, and copper. Each material's unique properties-such as spring back tendencies, hardness, or yield strength-can significantly impact the stamping process. At Shih Yeh, we leverage our extensive experience to account for these characteristics, ensuring smooth production and exceptional results. By carefully considering material feature, we achieve precise dimensions and meet customer requirements for custom-stamped parts.

Whether you need small and precision components for electronics or robust parts for machinery, appliance, or motorcycles, Shih Yeh's expertise in material handling and 30 years of stamping experience make us your trusted partner for high-quality, custom solutions.

- Related Products

Custom Aluminum Mudguard for Motorcycles - Advanced Stamping and Anodized Finish

This motorcycle mudguard is made from durable aluminum alloy, designed for both strength and precision. Utilizing advanced stamping technology, Shih Yeh tackles...

DetailsPrecision Metal Stamping of Stainless Steel Components for Medical Devices

This small, precisely shaped metal stamping part is essential for medical and healthcare devices, tailored to meet the stringent standards of precision...

DetailsPrecision Stainless Steel Pump Part with Progressive Die Stamping

Shih Yeh manufactures a wide range of metal stamped components, including precision pump parts. This pump part is made from 0.8mm-thick stainless steel...

Details